For detailed information, other images and documents, please select individual articles from the following table.

ASSY®plus 4 A2 TH glass strip screw Black A2 stainless steel, partial thread, top head

Special partial-thread screw made of high-quality, austenitic A2 stainless steel with small top head and milling ribs for gap-free fastening close to edges of delicate glass strips or skirting boards in outdoor areas constantly exposed to weathering

Register now and access more than 20,000 products

Variants

Register now and access more than 20,000 products

RW recess ensures optimal power transmission

- Larger contact surface at the bit offers increased power

- More stability, one-handed working and precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for multiple screw diameters

- Compatibility with previous AW recess

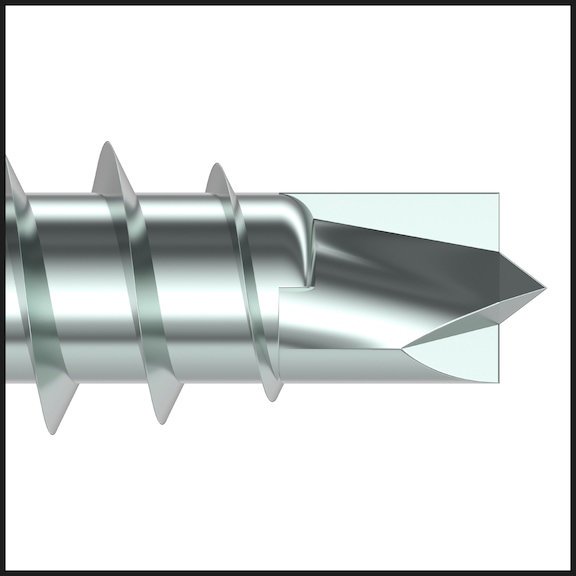

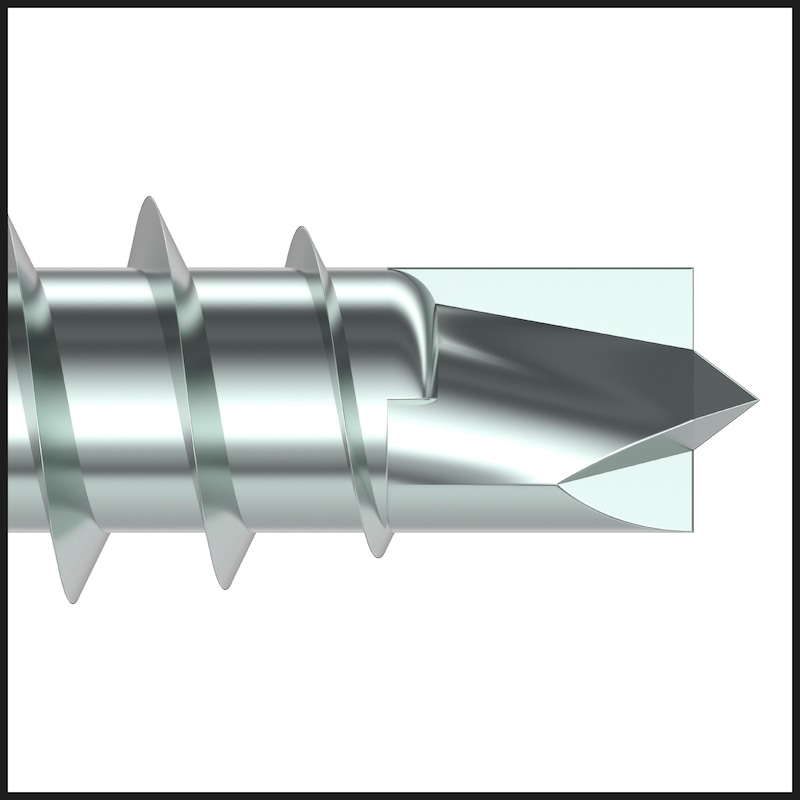

Precise positioning and very clean drilling due to advanced centring drill tip

- Chip-free positioning and drilling

- Powerful and precise drilling due to drilling cutting edges (similar to a Forstner bit)

- Centring pin ensures precise positioning on hard surfaces without slipping

- Quick screwing due to smooth thread start

Easy countersinking in hardwood and softwood

- Visually appealing connections due to lens-shaped, rounded head

- High milling performance and chip collection for clean countersinking of the head in softwood/hardwood

- For universal use in timber and metal connections due to milling pockets integrated in the countersunk head

- Can be combined with 90° metal countersinks

Maximum reliability of the screw connection

- Asymmetrical single-start thread

- Through optimal combination of drill tip and thread geometry

- Excellent anchorage in wood due to asymmetrical arrangement of thread flanks

Stainless use for accessible timber connections in outdoor areas exposed to weathering

- Made of austenitic, non-magnetic and non-rusting A2 stainless steel

- Can be used in a rural or urban environment or in an industrial atmosphere without significant exposure to chlorides or SO2

- With anti-friction coating for easy screwing

- We recommend using the Würth software or corresponding design aids for planning and designing your installation. Dimensioning of ASSY screws can be carried out in the Würth timber construction software from a screw dia. of 5 mm

- ASSY 4, ASSYplus 4 and ASSYplus 4 VG chipboard screws are optimised for use in wood and engineered wood. For applications in plastic anchors where a reduction in the admissible load may occur, only use screws without an optimised thread tip (tip with milling ribs, drill tip, self-clearing groove etc.), such as the ASSY D screws with countersunk head or pan head

Approved in accordance with ETA-11/0190

The requirements of the European Technical Approval (ETA) must be observed.

For wood-to-wood connections designed to be joined tightly

The partial thread starting immediately below the shank allows for wood-to-wood connections designed to be joined tightly. In this case, the thread is positioned entirely in the lower component.

Can be used for outdoor applications and utilisation class 3

- For optimal use of the screw, use the RW bit that fits exactly

- Partial-thread screws are ideal for connecting timber components. To ensure the components are optimally joined, the components must not be thicker than the length of the screw shank

- ASSY screws are approved for quasi-static loads

- ASSY stainless steel screws can be used to install hardwood decking and flooring. Pre-drilling is recommended for tropical timber with high bulk density

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!